The new Deceuninck recycling plant was opened in the Belgian city of Diksmuide. The company investmen is one of the largest of its kind in Europe. From now on Deceuninck will be able to use 100% recycled material to create new PVC window profiles.

PVC is a very durable material with low maintenance - it is estimated that plastic windows can approximately be used up to 50 years. Thanks to its advantages, PVC has become the most popular material used by manufacturers of window and door joinery. But nowadays we need to ask oursevles what to do with the growing number of profiles that the owners consider to be unnecessary or outdated? In the interests of the environment and sustainable development, the supplier of HENSFORT profiles decided to produce profiles using the recycling method.

ADVANTAGES OF RECYCLING PROFILES

- PVC profiles can be recycled up to 20 times without their quality interference

- Limitation of CO2 production from two tonnes to 135 kg (when producing one ton of profiles)

- Reducing environmental pollution

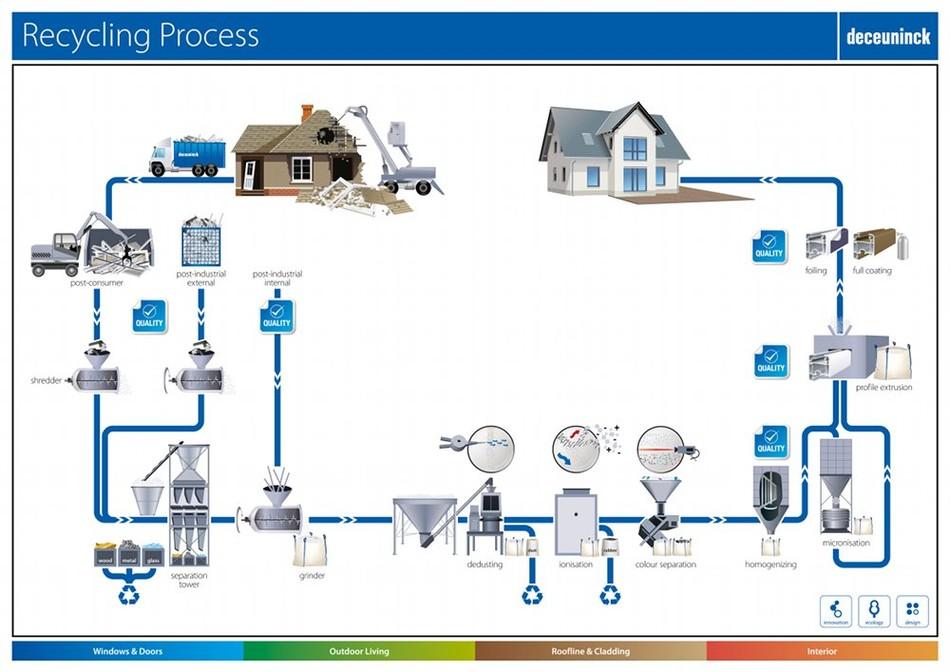

The latest technology used in the plant allows the recycling of material in all colours and compositions. During the recycling process, the profiles are crushed, sorted by colour and material, and all impurities are removed. The material is then granulated and becomes an ideal alternative to the primary material. Morevoer, it is used to extrude new PVC window profiles.

Deceuninck has been consistently investing in recycling for almost 25 years, being able to boast of the highest and environmentally friendly quality of PVC under the name Eco Power Core. Its advantages can be seen in the PVC HENSFORT ECOREINA system.

Source: Deceuninck